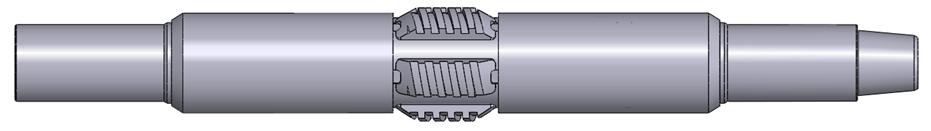

Blade Retrievable New-type Scraper (Patent product)

-

Brief introduction

Before running completion string tools, scraping operation is necessary for casing packer, hydraulic anchor setting position etc. Circulating port area between conventional scraper and annulus space could not satisfy requirements of replacing mud well. So after pulling up scraping string and running cleaning string tools for cleaning well, well flushing and mud replacement operation, which cause of running/pulling up string repeatedly and completion low efficiency. About this problem, our factory research and design hydraulic scrape & well flushing integrated tool.Tools are designed as required for running tool, scraping casing wall, closing scraper blade, well flushing, mud replacement etc. One time of running string tools, could accomplish scraping casing wall, well flushing and mud replacement.

Former scraping casing wall and well flushing need two times of running and pulling up string tools, this type of tool combine two operations and could start well flushing and mud replacement after scrapping casing wall directly without pulling up string tools, which improve completion efficiency and one time operation success rate.

-

Structure feature

Connect sleeve type switch below scraper. After scrapping and need to start cleaning well, mud replacement, well flushing etc, drop ball valve to seat on sleeve type switch, increase string pressure to force two cylinders of scraper moving toward each other and compress expanding blade back to chamber. Increase pressure continuously to open circulating port on sleeve type switch. After blade back to chamber, annulus space between scraper and casing is enlarged. It could improve efficiency of mud replacement and well flushing, accomplish two operations in one time of running string tools, decrease running and pulling up string tools to reduce production cost.

-

Technical specification

Max. OD (mm) Ф183.5 Max. cylinder OD (mm) Ф156 ID (mm) Ф40 Length (mm) 1545 Suitable casing size 7 7/8’’ Service circumstances Mud, crude oil, natural gas, water Working temperature 0~150℃ Working pressure (MPa) 70 Thread connection 3 1/2’’IF. B×P